Propelling Aviation Forward: How Quantum AI will Transform the Maintenance Ecosystem

In Part One, we explored how Predictive Maintenance-as-a-Service (PdMaaS) can be localized to capture and process real-time data from eVTOL and other aircraft to enable predictive fleet management. In Part Two of this four part series, we’ll explore how Quantum Artificial Intelligence (Quantum AI) and predictive analytics are transforming raw data into actionable AI insights.

The Role of Quantum AI in Predictive Maintenance

Traditional predictive maintenance relies on conventional data analytics, which often struggles to handle the complexity, scale, and real-time requirements of advanced aviation systems. Quantum AI introduces a revolutionary approach, unlocking unprecedented computational power to address these challenges. BEYONDx Advisors is focused on helping our clients commercialize, unlock and realize their desired outcomes by introducing Quantum AI capabilities such as:

Processing High-Dimensional Data - Quantum AI excels at analyzing complex, high-dimensional datasets generated by eVTOL systems, including telemetry metrics, IoT subsystem data, and flight operations logs. By rapidly identifying patterns and correlations that traditional systems cannot, it delivers insights with speed and precision.

Advanced Predictive Algorithms - BEYONDx’s Quantum AI services will use localized cutting-edge algorithms to help you predict failure points, estimate component lifespans, and recommend optimal maintenance schedules. For example, thermal anomalies in high-density batteries or subtle irregularities in motor vibration are flagged well before they impact safety or performance.

Dynamic Decision-Making - Quantum-enhanced machine learning enables adaptive decision-making. Maintenance recommendations evolve in real time based on operational conditions, weather data, and fleet utilization, ensuring just-in-time interventions that minimize downtime and costs.

The Predictive Analytics Framework

BEYONDx’s Quantum AI-powered PdMaaS services can be localized to transform raw data streams into desired actionable insights through a structured predictive analytics process. The process is localized in order to accommodate the operations needs, and the key components are as follows:

Anomaly Detection

Quantum Advantage - Quantum AI identifies deviations in operational data, such as overcurrent in propulsion systems or voltage drops in avionics with speed and accuracy.

Result - Early detection of potential failures allows operators to address issues proactively, reducing the risk of unscheduled downtime

Remaining Useful Life (RUL) Estimation

Quantum Precision - By analyzing wear trends and usage patterns, Quantum AI calculates the remaining lifespan of critical components.

Result - Operators can plan maintenance activities with precision, extending component life while avoiding unexpected failures

Maintenance Optimization

Quantum Efficiency - Quantum algorithms will be developed to optimize your maintenance schedules by considering factors like aircraft availability, technician resources, and regulatory compliance.

Result - Reduced operational disruptions and maximized fleet utilization.

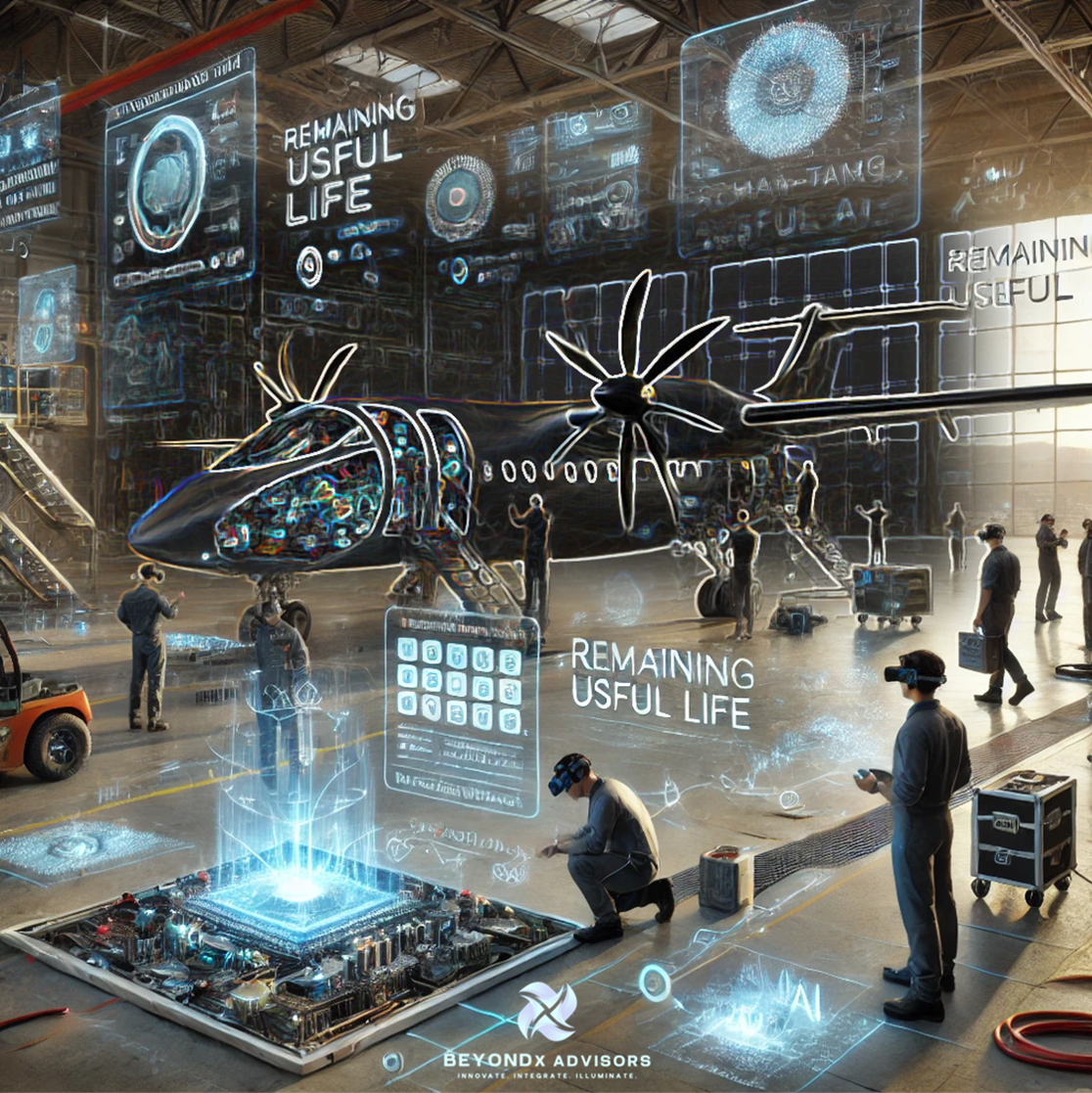

Visualizing Insights with Augmented Reality (AR)

BEYONDx’s PdMaaS services can bridge the gap between advanced analytics and on-the-ground execution through intuitive interfaces such as:

AR Maintenance Dashboards - Technicians equipped with AR glasses or tablets can visualize Quantum AI-generated insights in real-time, including diagnostics, RUL estimates, and maintenance instructions.

Collaborative Platforms - Data is accessible across teams, ensuring seamless communication between operators, maintenance crews, and regulatory bodies.

Mitigates Disruptions and Enhances Efficiency, Safety, Compliance, and Just-in-Time Maintenance

BEYONDx’s Predictive Maintenance-as-a-Service (PdMaaS) can leverage and localize Quantum AI and Augmented Reality (AR) technology, to provide maintenance crews and operators with real-time, actionable insights. By merging advanced analytics with intuitive AR interfaces, the platform ensures that disruptions are minimized, efficiency is maximized, and safety, compliance, and just-in-time maintenance become standard practices. Here are some focus areas for Quantum AI with Augmented reality :

Real-Time Visualization of Quantum AI Insights

AR-equipped technicians can access comprehensive dashboards through glasses or tablets that display Quantum AI-generated data. This real-time visualization provides unprecedented clarity and accuracy, enabling faster decision-making and better execution. Here’s some examples of the key areas of focus:

Diagnostics and Anomaly Detection:

How It Works - Quantum AI analyzes live telemetry data, IoT-enabled subsystems, and operational logs to identify deviations from normal operating parameters. For example, an AR dashboard might highlight a thermal anomaly in a high-density battery or irregular vibrations in a motor.

Impact - Technicians can instantly identify and focus on critical maintenance issues, avoiding the need for time-intensive manual diagnostics. This mitigates potential disruptions caused by undetected problems.

Remaining Useful Life (RUL) Estimates:

How It Works - Quantum AI calculates the RUL of key components based on usage patterns, stress factors, and historical performance. AR interfaces visually display these predictions, allowing technicians to prioritize tasks.

Impact - Predictive insights enable technicians to replace or service components just before they fail, ensuring just-in-time maintenance and avoiding premature part replacements.

Maintenance Instructions and Procedures:

How It Works - Quantum AI integrates aircraft-specific maintenance manuals and data into AR dashboards. Technicians receive step-by-step visual guides tailored to the identified issues.

Impact - Streamlined workflows reduce errors and accelerate task completion, improving overall efficiency and safety.

Seamless Communication Across Teams

Quantum AI’s ability to centralize and distribute data ensures that all stakeholders, operators, maintenance crews, and regulatory bodies have access to the same up-to-date information.

Here’s some examples of the key focus areas for eVTOL

Centralized Data Access:

How It Works - The platform consolidates data from telemetry systems, IoT sensors, and maintenance logs into a single cloud-based interface. AR-enabled devices access this data in real-time.

Impact - Technicians, managers, and compliance officers work from a unified dataset, eliminating miscommunication and ensuring consistent actions.

2. Team Collaboration and Task Coordination:

How It Works - AR devices allow multiple team members to view and interact with the same maintenance insights, whether on-site or remotely. Supervisors can provide guidance or approvals in real-time.

Impact - Enhanced collaboration reduces delays caused by misaligned priorities or unclear instructions, ensuring tasks are completed efficiently.

3. Regulatory Reporting:

How It Works - Quantum AI automatically generates reports aligned with Continuous Analysis and Surveillance System (CASS) requirements, which can be accessed through AR interfaces for review.

Impact - Regulatory bodies receive accurate, audit-ready data instantly, reducing compliance bottlenecks and ensuring adherence to safety standards.

How Quantum AI Enhances Maintenance Outcomes

Efficiency is paramount to maintaining operational continuity and minimizing downtime. BEYONDx’s Predictive Maintenance-as-a-Service (PdMaaS) will localize the power of Quantum AI and Augmented Reality (AR) to streamline maintenance workflows and optimize resource allocation. Real-time AR dashboards provide technicians with actionable insights at their fingertips, mitigating time-consuming manual diagnostics. At the same time, Quantum AI-driven just-in-time maintenance schedules ensure that critical tasks are prioritized, allocating tools, personnel, and parts precisely where they’re needed. Here’s some immediate areas of focus that can accelerate issue resolution and enhance overall fleet utilization:

Efficiency

Real-Time AR Dashboards:

How It Works - AR dashboards display Quantum AI-generated diagnostics in real-time, allowing technicians to see actionable insights without performing extensive manual checks. For instance, an AR interface can immediately highlight a battery nearing its thermal threshold or a motor showing signs of overcurrent.

Impact - This drastically reduces time spent troubleshooting and allows technicians to focus on resolving the identified issues quickly. Faster issue resolution ensures that aircraft can return to operation promptly, minimizing disruptions.

Optimized Resource Allocation:

How It Works - Quantum AI-driven just-in-time maintenance schedules identify the most critical tasks and allocate resources such as: tools, personnel, and replacement parts accordingly.

Impact - By preventing over-maintenance and minimizing redundant checks, the system reduces operational downtime. Technicians are deployed where they are needed most, improving overall workflow and ensuring optimal fleet utilization.

Safety

Early Anomaly Detection:

How It Works - Quantum AI continuously analyzes real-time data streams from telemetry systems, IoT-enabled subsystems, and flight logs to detect anomalies. For example, it might identify an irregular vibration in a propulsion unit or a voltage drop in an avionics system before these issues escalate.

Impact: By addressing these anomalies early, technicians can prevent potentially hazardous failures, ensuring the safety of the aircraft, crew, and passengers.

AR-Enhanced Step-by-Step Instructions:

How It Works - Maintenance procedures and troubleshooting guides are displayed as interactive, visual overlays on AR devices. For instance, a technician repairing a propulsion unit can view real-time diagrams, torque specifications, and step-by-step actions directly through AR glasses.

Impact - This reduces the likelihood of errors, particularly in complex or unfamiliar maintenance tasks. The combination of accurate instructions and visual aids enhances technician confidence and precision, resulting in safer operations.

Compliance

Automatic Data Standardization and Reporting:

How It Works - Quantum AI automatically processes and standardizes maintenance data to meet FAA requirements, including those outlined in CASS (Continuing Analysis and Surveillance System) and CAMP (Continuous Airworthiness Maintenance Program).

Impact - Maintenance activities are always aligned with regulatory standards, eliminating the risk of non-compliance. The system provides a clear audit trail for every action taken, ensuring transparency and accountability.

Centralized Data for Regulatory Audits:

How It Works - All maintenance logs, diagnostics, and compliance reports are stored in a secure, centralized platform. AR devices allow regulatory bodies to access and review this data seamlessly.

Impact - This simplifies the auditing process, allowing inspectors to verify compliance without delays or discrepancies. Operators can demonstrate their commitment to safety and regulatory adherence effortlessly.

Just-in-Time Maintenance

Predictive Analytics for Optimal Timing:

How It Works: Quantum AI uses predictive algorithms to analyze wear trends, stress factors, and operational data, determining the precise moment when maintenance is necessary. For example, it can predict the exact point at which a component will reach its end-of-life based on real-world usage patterns.

Impact: Technicians address issues just before they cause failures, avoiding unnecessary replacements or costly unplanned maintenance. This approach balances safety with cost-effectiveness, ensuring reliable operations.

Remaining Useful Life (RUL) Estimates:

How It Works: RUL estimates are displayed on AR dashboards, showing technicians the expected lifespan of components such as batteries, motors, and avionics. These estimates are continuously updated based on real-time data and operational conditions.

Impact: Maintenance can be planned more effectively, improving fleet availability. Operators can stagger interventions across their fleet to avoid grounding multiple aircraft simultaneously, ensuring smoother operations and better resource utilization.

Quantum AI and Regulatory Guidance

Quantum AI’s ability to handle large-scale data analysis ensures compliance with aviation standards such as Continuous Airworthiness Maintenance Programs (CAMP) and Continuous Analysis and Surveillance Systems (CASS). By automating data validation and regulatory reporting, BEYONDx’s platform streamlines compliance processes, reducing administrative burdens while maintaining safety and reliability. Here are sone of the key areas of CASS that Quantum AI will satisfy:

Quantum AI aligns with the Continuous Airworthiness Maintenance Program (CAMP) and the Continuing Analysis and Surveillance System (CASS) by providing advanced data processing, real-time monitoring, and predictive analytics capabilities. These systems ensure aircraft safety, operational efficiency, and regulatory compliance, and Quantum AI enhances their functionality in the following ways:

Enhanced Data Analysis - Quantum AI can process vast datasets generated by telemetry systems, IoT-enabled subsystems, and flight logs faster and more accurately than traditional methods. By identifying patterns and anomalies, Quantum AI ensures that maintenance schedules and actions are precise, proactive, and based on real-time insights.

Predictive Maintenance Optimization - CAMP and CASS rely on timely maintenance to ensure airworthiness. Quantum AI predicts potential failures or inefficiencies before they occur by analyzing wear trends, environmental stressors, and subsystem performance. This predictive capability minimizes unscheduled maintenance and mitigates operational disruptions.

Regulatory Compliance Support - Quantum AI aligns with CASS's emphasis on risk-based decision-making and surveillance by providing clear, actionable insights derived from regulatory guidance. For example, it ensures maintenance programs remain compliant with FAA standards by automatically flagging and prioritizing safety-critical tasks.

Risk-Based Decision-Making - Quantum AI supports CASS’s risk management framework by simulating maintenance scenarios and their outcomes. It evaluates the impact of different maintenance strategies on safety and operational performance, helping operators with actionable insights to make data-driven decisions.

Continuous Monitoring and Adaptation - Quantum bolts on to the CAMP and CASS SMS ecosystem to continuously monitor the effectiveness of maintenance activities. It identifies inefficiencies or gaps in the program and suggests adjustments to enhance compliance and operational readiness.

Key Quantum AI Benefits for Maintenance

The integration of Quantum AI into predictive maintenance delivers measurable benefits, here’s how :

Overall Benefits for Manufacturers, Operators and Regulators

Increased Safety - Early anomaly detection ensures critical issues are addressed before they pose risks.

Cost Savings - Optimized maintenance schedules reduce unnecessary interventions and extend component life.

Operational Efficiency - Just-in-time strategies minimize downtime, keeping fleets operational longer.

Quantum AI Benefits for the MRO SMS for Part 121 and AAIP for Part 135

The integration of Quantum AI into the Maintenance, Repair, and Overhaul (MRO) Safety Management System (SMS) brings significant benefits for both Part 121 operators (scheduled air carriers) and soon-to-be Part 135 eVTOL operators (on-demand and charter services). The solution enhances predictive capabilities, optimizes resource allocation, ensures compliance, and mitigates risks, transforming traditional maintenance practices into a data-driven, predictive ecosystem.

Here’s are the key benefits:

Key Benefits for the Safety management System (SMS)

Enhanced Predictive Maintenance:

Part 121 SMS ‘CAMP’ and Part 135 AAIP both prioritize safety and operational continuity. Quantum AI helps identify potential failures before they occur by analyzing telemetry, IoT subsystem data, and flight logs, enabling operators to take corrective action before issues disrupt operations.

Risk-Based Maintenance:

Quantum AI aligns with the SMS principles of identifying, assessing, and mitigating risks. It continuously evaluates maintenance schedules, performance metrics, and operational risks, ensuring compliance with safety standards while reducing unnecessary interventions.

Compliance Monitoring:

Quantum AI automates the alignment of maintenance activities with Continuous Airworthiness Maintenance Program (CAMP) requirements for Part 121 operators and Approved Aircraft Inspection Program (AAIP) for Part 135 operators. This ensures efficient compliance to regulatory standards.

Operational Efficiency:

By analyzing maintenance trends and workload distribution, Quantum AI helps allocate resources efficiently, ensuring minimal downtime and maximum aircraft availability.

Data-Driven Reporting:

Quantum AI generates detailed reports that can be used for regulatory audits, internal reviews, and post-incident analyses. This supports both MRO and SMS compliance, providing transparency and accountability.

Key Benefits for a Part 145 MRO for Part 121 Operations

For scheduled air carriers operating under Part 121; Part 145 MRO services typically include:

Line Maintenance:

Routine inspections and minor repairs performed between flights.

Quantum AI’s Role - Identifies patterns in recurring issues to streamline line maintenance activities.

Heavy Maintenance:

Scheduled overhauls and deep inspections, including D-checks.

Quantum AI’s Role - Optimizes scheduling for these resource-intensive processes to reduce fleet downtime.

Component Maintenance:

Repair or replacement of critical components such as avionics, engines, and landing gear.

Quantum AI’s Role - Provides predictive insights on component wear and remaining useful life (RUL).

Structural Repairs:

Repairs to fuselage, wings, or other structural components.

Quantum AI’s Role - Detects anomalies in telemetry data to identify potential structural issues early.

Contractual Modifications and Upgrades:

Installation of new systems or upgrades for compliance or operational improvements.

Quantum AI’s Role - Ensures accurate scheduling of 3rd party maintenance contractors and minimizes operational disruption.

Key Benefits for a Part 145 MRO for Part 135 Operations

For on-demand and charter services under Part 135; MRO services are tailored to smaller fleets with specific needs:

Routine Inspections:

Pre-flight and post-flight checks to ensure airworthiness.

Quantum AI’s Role - Automates anomaly detection for faster and more accurate inspections.

Engine and Propulsion Maintenance:

Routine and unscheduled maintenance of engines and propulsion systems.

Quantum AI’s Role - Tracks engine performance metrics to prevent in-service failures.

Avionics and Electrical System Maintenance:

Troubleshooting and repair of avionics and electrical systems.

Quantum AI’s Role - Identifies irregularities in voltage, current, and signal integrity.

Interior and Cabin Maintenance:

Focused on passenger comfort and safety.

Quantum AI’s Role - Tracks wear trends to ensure timely replacements.

Specialized Maintenance Programs:

Programs for specific aircraft types or unique operational needs.

Quantum AI’s Role - Customizes predictive models to match the unique configurations of charter fleets.

Added Value for Charter and eVTOL Operators (Part 135)

Fleet Optimization:

For smaller, diverse fleets, Quantum AI ensures maintenance is scheduled around operational demands, minimizing downtime and maximizing revenue.

Fuel, Battery and Cost Efficiency:

By monitoring propulsion system performance, Quantum AI identifies opportunities for fuel and/or energy savings and reduced maintenance costs.

Regulatory Compliance:

Automates compliance with Part 135-specific AIPP requirements, including mandatory inspections and component life tracking.

Real-Time Insights for Operators:

Provides real-time dashboards for charter operators to monitor fleet health, operational status, and upcoming maintenance requirements.

Customer Experience:

Ensures reliability and safety, boosting customer confidence in the operator’s services.

Looking Ahead: The Future of Predictive Maintenance

As we’ve explored in this article, Quantum AI is a transformative solution with Quantum subscription services ready to redefine the aviation maintenance landscape today. By combining predictive analytics with augmented reality and localized data solutions, the BEYONDx localized advisory services empowers operators to mitigate disruptions, enhance safety, manage compliance, and achieve efficient just-in-time maintenance..

Stay tuned for Part Three of this four part series: “Delivering Quantum AI for Predictive Maintenance: From Data to Intelligent Action.” In the next article, we’ll explore the inner workings of Quantum services that can realize the desired outcomes for predictive maintenance . We’ll explore the process of data ingestion, quantum AI subscription services and how these insights can be bolted on to and through real-time platforms.

Ready to Elevate Your Maintenance Strategy?

Click here to schedule a free consultation with BEYONDx Advisors today and discover how Quantum AI-powered predictive maintenance can transform your operations, enhance safety, and maximize efficiency. Let us help you X-C-E-E-D your Xpectations.